To give the necessary support to the programme of rehabmlmtation of cocoa plantations in Bahia, the State and Federal authorities together wmth the producer’s co-operatives (CREDICOOGRAP and COOGRAP) decided to create the ‘Instituto Biofâbrica de Cacau’. This organisation is in charge of the mass multmplication of witches’ broom resistant clonal varieties selected and recommended by CEPLAC for replanting old cocoa farms and for the establmshment of new plantings. The details of the functioning of thms unit are given as well the protocol for raising the rooted cuttings.

Introduction

The cocoa plantations of the State of Bahia have suffered badly due to the severity of the witches’ broom disease, caused by Crinipellis perniciosa Stahel. The disease was first identified mn these cocoa areas in 1989. The cocoa economy of the area, already badly affected by low productivity in the mid-1980’s and the current cocoa price crisis, suffered further with the spread of witches’ broom disease and this has been a major factor in the process of regional impoverishment. Since then, an ambitious programme for the rehabilitation of the cocoa plantations was implemented involving both clonal and seminal resistant varieties. The project of the ‘Instituto Biofabrica de Cacau’ (hereafter identmfled as ‘Biofâbrica’) was initiated to fulfil the farmers urgent need for resistant varieties to accelerate this programme of rehabilitation.

Given the highly favourable conditions for the spread and development of the fungus, the disease soon reached epidemic proportions in almost all of the cocoa plantations, causmng plant debilitation, a significant drop in production and death of trees. Because of the lack of an efficient means to control the disease, many rural properties were abandoned. Many cocoa growers are investing in other agricultural activities. This has been leading to the degradation of the natural resources in the remaining areas of the Atlantic Forest, causing alterations and imbalance in the ecosystems.

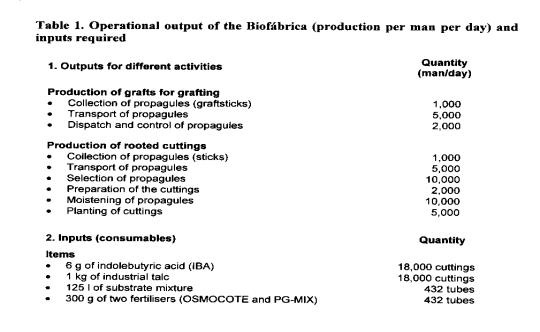

For all these reasons, the Agriculture Bureau of the State of Bahia and the Federal Government, represented by CEPLAC, formed an alliance with the co-operatives of producers (CREDICOOGRAP and COOGRAP) for technical, managerial and financial co-operation to give effective support to the rehabilitation programme for the cocoa plantations. The settmng-up phase of the Biofabrica project began in December 1997 and ended in October 1999. It has as its objective the mass multiplication and distribution to cocoa growers of the witches’ broom resistant cocoa clones recommended by CEPLAC. The overall cost for the implementation of Biofabrica was around two million US dollars. The rooting house and nurseries have the capacity for a daily production of 50,000 rooted cuttings but at present a shortage of cuttings is restricting the daily production to approximately 10,000 rooted cuttings (see Table 1). The price of one budstick, with three buds, for grafting is currently about 5 US$ cents whereas the rooted cuttings cost 15US$ cents (the latter still being subsidised).

The State Ordinance of November 16, 1999 gave the Institute Biofabrica de Cacau the administrative autonomy and flexibility to allow it take on a political role and to act as a catalyst for government actions for the cocoa sector as well as for other crops. As part of the programme for the year 2001, the institute intends to continue to exploit the current facilities of Biofâbrica and to open a new site for multiplication of improved cocoa clones in an area located in the southern part of the State. This facility would contain another 100 hectares of multiplication gardens to be filled with other clones recommended by CEPLAC.

The technical details of the functioning of Biofábrica

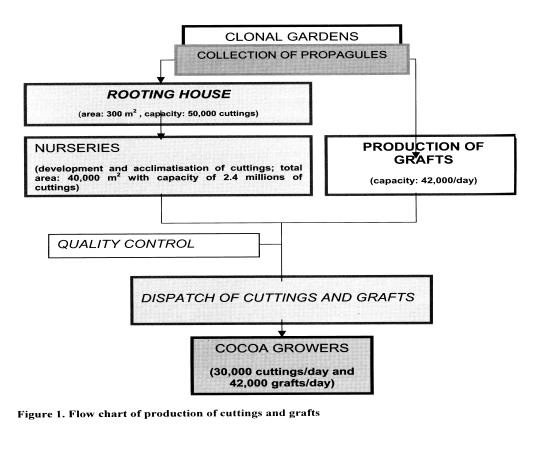

The technical procedures adopted in the different phases of the productive process as well as the necessary work routines for the operation of Biofabrica are summarised in Figure 1 and presented in detail hereafter,

Source of propagules supply to Biofábrica

<

Besides the clonal gardens, the Biofábrica institute contains offices for administration, facilities for preparation of rooted cuttings and 20 nurseries irrigated by an automated system of intermittent atomisation with the capacity to produce four million rooted cuttings per year. The primary operational cost of the clone gardens and facilities at Biofábrica is approximately US$ 600 thousand dollars/year.

This year, the Bureau of Agriculture of the Bahia State is financing the planting of another 100 hectares of clone gardens for the multiplication of new resistant clones deployed by CEPLAC. These clone gardens are expected to start providing propagules from 2001 onwards.

Working procedure for production of rooted cuttings

The procedure has been standardised for the utilisation of the non-woody portion of plagiotropic fan branches only, cut at 30 cm from the terminal apices. The cuttings were originally prepared so that the final cutting had 1/3 of the leaf blade and no terminal bud. Nowadays, they are prepared so that the cuffing retains 2/3 of the leaf blades and the terminal bud.

Once collected, the material is put inside polystyrene boxes, hydrated and then transported to the rooting house where the cuttings are prepared (with five buds and with 2/3 of leaf blades). During preparation, the cuttings are continuously hydrated. Before planting the cuttings into tubes containing 288 ml of rooting mixture, the base of the cutting is treated with an indolebutyric acid (IBA) solution at 6,000 ppm. The rooting mixture used in the tubes is composed of 50% commercial product containing vermiculite, perlita and pine tree husk powder, and 50% of ground coconut fibre. To this mixture are added 300 g of each of two fertilisers (10-06-20 and 14-16-18 of NPK, respectively). The tubes are placed on trays with 54 units in each.

The cuttings, once planted in the tubes, are transferred to the nurseries where they are shaded by a 70% sunscreen. They are generally maintained under a regime of irrigation, consisting of atomising for 30s at intervals of 4 to 5 mm, over a period of approximately 60 days. At the end of this period the roots can normally be seen growing out of the tubes. At this point the cuttings enter a seven day acclimatisation stage where the irrigation interval is changed to every 10 minutes. After that, the frequency of watering continues to be reduced progressively until the plants are only irrigated three times per day. The scheme of irrigation may however vary according to the prevailing climatic conditions. To produce a rooted cutting ready for field planting takes on average four to five months, depending on the clone and the climate. The operational output of rooted cutting production by this procedure currently varies from 2,000 to 2,500 cuttings/day.

From 2001 onwards, Biofabrica will investigate the re-rooting of primary branches derived from these rooted cuttings during the acclimatisation stage in order to increase the number of propagules. At present, the net take for jxoducing these secondary rooted cuttings is around 60%, Studies are underway to improve the success rates and efficiency of the procedure for obtaining secondary rooted cuttings. The cuttings obtained from this source take from 10 to 12 months in total to achieve the ideal level of development for field planting.

Operational process for the production of rooted cuttings on a semi-industrial scale

The production process described hereafter involves all the stages from the collection of the propagules in the clone gardens to the distribution of grafts and cuttings to the final consumer.

Collection of propagules

Transport of the propagules

Substrate preparation and filling of the tubes

Cleaning of trays and tubes

The filling of tubes

Reception and preparation of the propagules for rooting

Cleaning of the environment and asepsis of the tools

Planting of the cuttings

The nurseries

Fertilisation of the cuttings

Cleaning and pestldisease control in the nurseries

Dispatch of cuttings

Transportation of the cuttings

Preparation and packing of branches for on-farm grafting

The branches collected for grafting purpose are maintained with leaves and cut in such a way that each fan branch supplies two to three grafts, each with five axillary buds. The extremities are treated with paraffin wax and then the stem segments are wrapped in moistened newspapers and placed in polystyrene boxes for transport to the place

where they will be used. The recommended procedure at the farm level is grafting onto basal chupons by using one or two grafts on each chuponn.

References

Eagundes N. B. 2000. Eucalyptus cloning. Pages 92-94 in Proceedings of The Technical Meeting State of Knowledge on Mass Production of Genetically Improved Propagules of Cocoa”, 1gth — 23rd October, 1998, llheus, BA, Brazil. CEPLAC, Itabuna. Brazil.

Palacios J 6. 2000. Disponibilidade de material de clonagem no campo: Logistica, operaçao/producaoe custos. Pages 98-103 in Proceedings of The Technical Meeting “State of Knowledge on Mass Production of Genetically Improved Propagules of Cocoa “, it —23M October. 1998, llheus, BA, Brazil. CEPLAC, Itabuna, Brazil.

Biotech Glossary |

Bioinformatics |

Lab Protocol |

Notes |

Malaysia University |

Mass Multiplication on a Semi-industrial Scale of Cocoa Clones by Rooted Cuttings in Brazil

Jesus B. Palacios and Wilson R. Monteiro

1- Instituto Biofábrica de Cacau, Uruçuca, Bahia, Brazil

2 - Universidade Estadual Santa Cruz —UESC, llhéus, BA, Brazil

3 - CEPLAC - Centro de Pesquisas do Cacau, CP7, 45600-000, Itabuna, Bahia, Brazil

The sources of propagules are the clone gardens established in an area of 50 hectares divided in to 17 blocks. Seventy percent of the area is planted with the clones TSH 516, TSH 565, TSH 1188, EET 397 and CEPEC 42 and the remaining 30% with TSH 774, TSA 654, TSA 656, TSA 792 as well as some other resistant clones selected by CEPLAC from various cocoa farms. The first clone gardens were planted in May 1998, usually by grafting on basal chupons. Currently, 200,000 budsticks are collected from these clone gardens per month for distribution to growers (mainly used to graft onto adult trees on their farms). The same numbers of softwood cuttings are collected each month for production of rooted cuttings at the Biofabrica area.

The method for production of rooted cuttings was developed by the researchers at CEPLAC in collaboration with the Veracel Celulose S. A. and with the operational and technical support of Biofábrica (Fagundes 2000; Palácios 2000). After several adjustments, this procedure has been improved substantially resulting in an increase in lake” from 55 to 80%.

The collection of propagules in the clone gardens begins at 05:30 in the morning. Fan branches are cut with the aid of pruning scissors. The branches are selected according to their diameter: those with diameters between 15 and 20 mm are destined for grafting, while those with diameters between 3 and 5 mm are used for rooted cuttings. Special care is taken to ensure that the clone gardens are maintained so that they can provide an abundant supply of high quality propagules. Branches are collected from each clone individually and these batches of branches are carefully labelled.

Stems with larger diameters are transported to the distribution shed, while the others are sent to the rooted cutting preparation house. As stated above, it is essential to keep the material properly hydrated to ensure good success rates in the rooting phase.

This operation is done in a unit that is subdivided as follows: a) room for preparation of cuttings (180m2); b) room for the preparation of the substrate (56m2); c) stock room (4am2); and d) toilets (am2). In preparing the substrate for filling the tubes, 150 I of a commercial organic compost mix is added to the same amount of powdered coconut fibre. Three hundred grams of each of the two chemical fertilisers are then added. The substrate is initially dry-mixed, with the help of a cement mixer, to provide good homogenisation and, after that 501 of water is added.

The cleaning and asepsis of the trays and tubes is done before the tubes are filled, by washing with jets of water at 80°C for 10 seconds.

The tubes are placed in appropriate trays and filled with the humidified substrate. During this operation the trays and their tubes are submitted to a vibration treatment for eight seconds to guarantee an adequate compactness of the substrate. Once this is completed, the trays are transferred to the room where the planting of the cuttings will be accomplished.

Branches of smaller diameter collected in the clonal gardens are taken to the reception room, where they are kept humid. These branches are distributed over several tables adapted for the preparation of the cuttings. The trained workers begin the preparation of the cuttings by cutting them, with aid of special scissors, in to segments with four to five axillary buds and leaving three leaves with 2/3 of each leaf blade. In this phase, any branch that does not meet that quality standard set by Biofébrica is discarded. The prepared cuttings are placed in the upright position inside a small plastic box containing 30 mm of water. The root induction treatment and the planting of the cuttings will normally take place on the same day as the propagules are collected. However, when it is not possible to treat all the material collected on one day, any remaining propagules are wetted and maintained inside the reception room in polystyrene boxes. On the following day, these will be the first materials to be prepared. It is known that the success rates for rooting these materials will be lower. All discarded materials are taken back to the clonal gardens and spread in the area,

At the end of the day, the working rooms are swept and are more thoroughly cleaned at the end of every week. The working tools used in the preparation of the cuttings, as well as the boxes used for storage of the propagules, are disinfected at the end of each day, by immersion and washing in a chlorine solution at 0.2%,

Once the cuttings are prepared, they are treated with a root inducing compound (indolebutyric acid 6,000ppm mixed in neutral talc). The cuttings are planted in the centre of the tubes and the substrate is compressed to provide the right firmness. Once the planting is completed, the trays are transferred to the nursery.

The treated cuttings will stay in the nurseries during the whole period of root formation and acclimatisation. The first phase, involving the development of roots and of primary branches, takes approximately 60 days. During this period, the cuttings are humidified under a regime of intermittent water atomisation in such a way that the humidity at the leaf surface is constantly 100% and that of the nursery environment between 60 and 70%. The average temperature inside the nurseries is approximately 25°C and the light intensity is approximately 70% of full daylight. After 60 days, the frequency of atomisation is decreased progressively as the cuttings enter the acclimatisation stage. Thus, in the first week, the wetting interval increases to 10 minutes and in the second week to 20 minutes, with each irrigation event lasting 2 to 3 minutes. After this, the plants are irrigated for 5 minutes every 3 hours and, finally, for 5 minutes every 6 hours. On rainy days the irrigation regime may be modified.

The fertilisers are mixed together in appropriate proportions and quantities in a plastic box in the machinery house that controls the irrigation of all the nurseries. The initial application of both macro- and micro-nutrient fertilisers is made to the cuttings via the irrigation system after 50 or 60 days. Thereafter the fertilisation is repeated every 10 days.

The cleaning operation involves the removal of dead leaves, as well as the removal of the tubes containing cuttings that failed to root. The aim is to eliminate possible pest and disease sources, The waste materials are discarded and the tubes and trays sent to the wash section for cleaning with hot water jets. Insecticides and fungicides, applied via irrigation at the end of the day, are applied weekly to control and prevent pests and diseases. Additional pest and disease control is carried out as required. The nurseries are disinfected after all the cuttings have been dispatched by the application of a solution of chlorine and fungicides. The treated nursery is isolated with plastic curtains. The treatment is made during the weekends to reduce staff exposure to the chemicals and prevent interruption of the other activities. Cleaning of the drains is done at intervals of 25 days, to ensure free drainage of the water and other debris.

The cuttings are generally ready to be transplanted to the field at the age of 120 days. In order to be dispatched, they must meet the quality standards defined by the State Authorities related to the Secretary of Agriculture. Any that do not meet these standards will be maintained longer in the nursery until they are suitable for dispatch to the farms. The cuttings are dispatched within the tubes in their respective trays (54 tubes per tray).

The rooted cuttings are transported in covered trucks to protect against sunshine and winds. The trays are accommodated in such a way that the risks of damage to the cuttings during the transportation are minimal.